| |

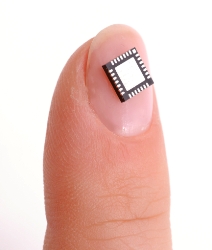

Cheap

processor intelligence is being built into virtually every controller chip

released today—chips which are no larger than a thumbnail! This runs the gamut

from sensors to communication chips to A/D and D/A chips to power chips to

microcontrollers. Yesterday’s 12" x 12" controller board, multi-card backplane

system, or three-card stack has been shrunk into single chip solutions with

USB, I2C, or SPI output! The result...appropriate board level form factors must

be re-thought. Cheap

processor intelligence is being built into virtually every controller chip

released today—chips which are no larger than a thumbnail! This runs the gamut

from sensors to communication chips to A/D and D/A chips to power chips to

microcontrollers. Yesterday’s 12" x 12" controller board, multi-card backplane

system, or three-card stack has been shrunk into single chip solutions with

USB, I2C, or SPI output! The result...appropriate board level form factors must

be re-thought.

Scaling down form factor footprint sounds easy enough, right? While smaller

semiconductors encourage smaller form factors for embedded applications, the

success of a form factor resides in having sufficient space for appropriately

defined connectors. Connectors have become, for lack of a better word, the

"bottle neck" to shrinking form factors. "Connectorology" is the key to

shrinking form factors appropriately for embedded OEM users.

The study of connectors and their mix of protocols, aptly coined

"connectorology," ensures OEMs maximize their efficiency and effectiveness. For

example, a "thumbnail" SOC chip offers several system level protocols users

might want to implement in their embedded application. To alleviate the burden

on the OEM, board level manufacturers are challenged with supplying a connector

to facilitate access to these protocols. Typically there are three approaches

to choosing a connector.

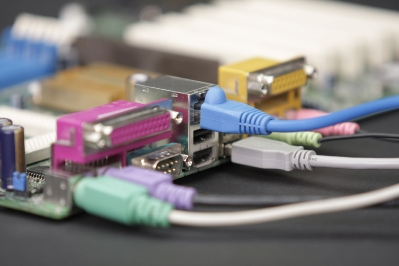

One way is to bring out each protocol supported by the CPU or SOC chip to

individual connectors. This approach typically works well for what is commonly

called a "reference design" board. The board size is defined by the number of

connectors required to communicate with all of the I/O options from the chip.

This board typically falls short of the needs of OEM users because the board is

maximized for the chip’s performance with little regard to the needs of an

embedded system. In this case, all types of I/O are equal and have an equal

position on the board which enlarges the physical dimensions of the boards not

to mention adds costs for multiple connectors (see Figure 1).

Figure 1

The second approach is for the board level manufacturer to randomly "stuff"

several protocols into a compact connector coming off the board with hopes that

it meets the user’s needs. While this approach is easy for the board level

manufacturer and appears at first glance to meet the need for smaller

footprints, it shifts a significant burden and cost to the user and adds bulk

in unsuspected places. Users find they need to purchase a customized "breakout"

board to gain access to the protocols or signals from the connector. In the end

what was saved on an "inexpensive" single board computer is spent in custom

cabling and mounting hardware (see Figure 2) needed to access the I/O—a cost

easily overlooked in planning a system.

Figure 2

Embedded OEM users often find board-to-board communication the most cost

effective and efficient value for their system. The best approach to choosing a

board-to-board connector scheme is to evaluate the I/O and communication

protocols required by the system, plus the power, reliability and energy

demands, not to mention the overall assembly environment and budget for the end

product. A complete system approach emphasizes the value of selecting a

popular, industry-supported board-to-board stacking standard which clearly

defines the appropriate mix of protocols for the system. This ensures that the

user does not have more cost or complexity than he or she needs burdening one’s

system on multiple levels including form factor size. It also ensures that the

user does have what he or she needs and therefore doesn’t have to add

expensive, bulky cables or breakout boards. A well-defined connector specifying

pre-defined protocols enables OEM users to gain valuable access to common

add-on I/O devices in the most efficient and effective space; the best example

of this is StackableUSB™ (see Figure 3).

Figure 3

|

| |

|

|