| |

|

|

Board-level system designers

have benefited from Moore's Law of exponential improvement in size, cost,

density, and speed over the years as processor boards have packed more

horsepower and raw computer power onto their boards, however, maximizing

efficiencies have been lacking. With the growing selection of smaller

microprocessors and ARM processors running at faster speeds, requiring less

power and packing more capabilities into single chip solutions, efficiency is

becoming the watch word of the day. The push for efficiency is also coming from

an economy that has become increasingly more concerned about speed for speed's

sake, especially as energy costs soar and landfills amass with discarded

electronics. Efficiency is in.

Today, smaller, lower-power processor boards can be mated with similarly

smaller I/O boards controlled by equally more integrated I/O chips from the

A/D, D/A, communication, mass storage, and sensors areas, thus creating a

Moore's Law effect in board-level products. Couple this with the advantages of

using USB, a serial protocol, as the communication link between these boards

and system designers have the tools they need to leverage untold efficiencies

in their system designs.

In the embedded world, momentum has been building for USB to be the I/O channel

of choice in embedded applications. This is in part a result of USB being the

one common serial interface between three distinctly different CPU cores:

microcontrollers whose speeds now reach over 80MHz, ARM processors which

operate comfortably in the 100MHz to 500MHz range and PC processors that reach

beyond the 1 GHz range. The trend to include USB in CPU cores and the

increasing number of USB ports included in those cores establishes it as the

most prolific I/O channel on the market.

Flexibility and scalability is a key advantage for achieving efficiency that

board-level manufacturers can offer systems designers. With USB as the I/O

channel, embedded designers are provided distinct advantages enabling them to

maximize efficiencies in their system designs. These advantages are enhanced

for the embedded user with StackableUSB™, a popular stacking protocol that

implements USB, I2C and SPI in a compact, rugged format conducive to industrial

control and measurement applications.

|

USB's Debut

USB has its roots as a serial protocol made popular on desktop PCs and laptops

as multiple protocols such as RS232 serial ports, floppy drives and printer

ports disappeared and a single protocol emerged to connect all devices to a PC.

As USB grew in popularity, the range of I/O devices it supports expanded

rapidly, and it quickly grew beyond just an interface for a mouse, keyboard and

printers to become the I/O channel of preference for everything from digital

cameras to iPods and portable hard drives.

Implementing USB on desktops requires a cable between the Host processor and

the USB Client or Device. In addition, on both the Host and Device side,

software is necessary to ensure the compatibility and the "plug-and-play"

features of USB. Typically there are three layers of software on both the Host

and Device side: 1) the controller driver; 2) the USB stack and 3) the class

driver for the Host or the function driver for the Device.

Most operating systems such as Windows or Linux implement the three layers of

Host software and are considered USB-ready. The tool chains that support

popular microcontrollers, such as the PIC24 and PIC32 from Microchip, have

built-in USB stacks providing the multi-layer USB software to users. I/O

manufactures are responsible for providing the Device software support that

ensures their "plug-and-play" participation with USB.

|

USB finding its way in Embedded:

StackableUSB

StackableUSB empowers USB in the embedded world by incorporating multiple USB

ports into a single stacking connector, eliminating the need for cabling. The

stacking format creates a rugged framework for building embedded systems.

StackableUSB electrically supports five USB root ports on the top side and five

on the bottom side of a single board computer as well as I2C and SPI. The

number of USB root ports available to the user is determined by the number of

USB ports supported by the single board computer. Additionally, each USB port

provided by the processor can be expanded using a Hub interface to provide for

an additional four to seven Devices.

To ensure mechanical compatibility, StackableUSB defines a new physical form

factor to implement embedded USB I/O, one that scales down the older,

traditional I/O boards to 1/4 the size of previous generations. These smaller,

yet more powerful, Device-side I/O boards measure 1-7/8" x 1-7/8" and can be

added to a system in a variety of ways. Depending on one's space constraints

and system design, the boards can be stacked together to form a rugged,

stand-alone, brick-like unit; they can be added to a carrier board

accommodating up to four StackableUSB Devices on any single board computer; or

each Device can be attached to the processor unit via a standard USB connector

and cable. The carrier board configuration is available for the more popular

SBC formats such as PC/104, EBX and EPIC form factors as well as VIA

Technologies' recent releases of the Pico-ITX and Nano-ITX form factors.

|

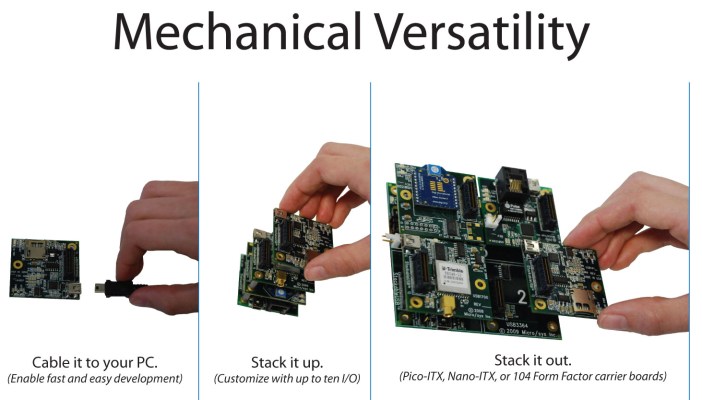

Enabling Packaging Efficiency

though Mechanical Versatility

Determining how to physically implement and attach USB Devices to an embedded

system has been one of the challenges facing embedded users. Previously there

has not been a standard form factor or mounting configuration to support

designers considering USB. This drawback has slowed the adoption of USB in

embedded applications. StackableUSB not only solves the problems but provides

several options to designers during system development and the final deployment

of the system.

Figure 1 shows the different ways StackableUSB modules can be combined into a

unique system. Consider an application for remote location sensing of a mobile

unit where space, in terms of surface area, is limited. Here, a ¼-size

StackableUSB host stacks a GPS module for detecting location and time, a Zigbee

Module for wirelessly communicating with central command or another mobile

unit, and an SD card reader to log its location at a given interval. Now

consider the exact same application, but where vertical height space is

limited. Here, the exact same StackableUSB modules are housed on a carrier

board allowing the system to make use of the available surface area across any

form factor. Then, at the end of the day, the SD card reader can be connected

to a PC via a traditional USB cable, allowing the logged data to be downloaded.

Figure 1

|

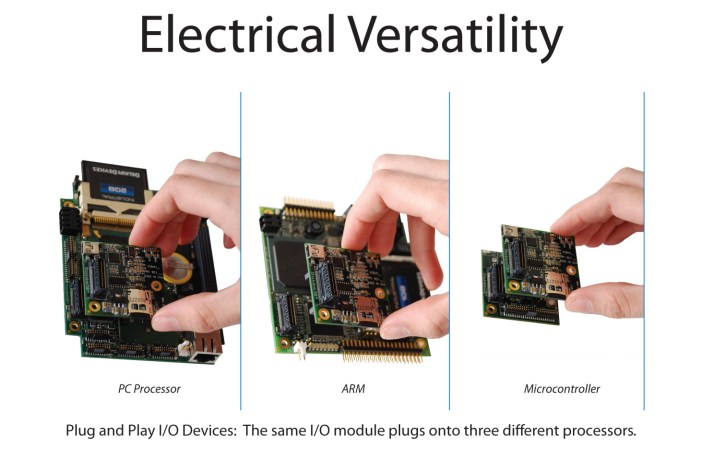

Enabling System Efficiency through

Electrical Interoperability

Similarly, as StackableUSB is blind to the form factor, it is also blind to the

Host CPU platform. Figure 2 shows a StackableUSB SD card reader connecting to a

PC Processor, an ARM Processor, and a Microcontroller. In addition, taking

advantage of USB's plug and play capabilities can create highly reliable and

robust systems. Consider an application where system parameters may need to be

updated in the field, and the system consists of three different sub-systems.

The same SD card reader can hold the new parameters and update each sub-system

individually when the module is connected to the host CPU as shown, without the

need for bringing the entire system down for a simple programming modification.

Figure 2

This ability to mix-and-match Host processors and Client, or Device I/O,

modules is the foundation of USB's electrical interoperability. This

inter-changeability serves users well because they gain advantages and benefits

that ease development, reduce costs and improve their time to market. Simply

put, OEM users gain because: 1) single board computers become more generic and

more easily interchangeable which drives down prices while maximizing

performance, 2) more generic and interchangeable boards reduce concerns around

the issue of "sole" source, 3) "end of life" cycles become less consequential

to OEM users because replacement units are easily integrate-able, and 4) making

system upgrades, revisions or downgrades can, with little difficulty, be

accommodated to take advantage of economies of scale or feature enhancements

for the OEM system.

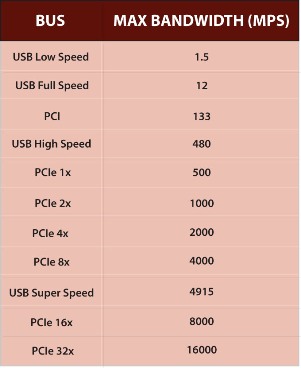

USB as a whole cannot be rivaled

by any of the more recent serial protocols such as the faster and higher

throughput PCI and PCI Express. When comparing the bandwidth of these protocols

(refer to Figure 3) USB's throughput has kept pace, and in the case of USB

Super Speed or USB 3.0, it rivals these protocols and in some cases exceeds the

performance of PCI Express. Additionally, USB is the only one of the protocols

that is portable across three different processor platforms and offers the

simplest implementation, eliminating the complex silicon interfaces, processing

power, and the software support required for PCIe.

Summary

As evidenced, Moore's Law has found its way into embedded board-level

applications with a multitude of benefits for the user, the number one being

efficiency. So just because you can go faster, be sleeker, or be more full

featured, doesn't mean you should. Efficient products maximized across multiple

platforms, implemented on smaller footprints, and capable of low-power

operation is the goal. USB and StackableUSB exemplify such a trend.

|

Figure 3

|

|

| |

|

|